Providing long-term and reliable corrosion protection for metal products has always been a core technological challenge in industrial manufacturing. Traditional coating processes often have limitations when facing harsh operating conditions.

Fluidized coating, as an advanced surface treatment method, provides an exceptional thick-film protective solution for metal components by empowering solid powders with fluid-like behaviors.

Basic Principles: The Fluidized Bed and Powder Rheology

The technical core of fluidized coating lies in the fluidized bed. A fluidized bed is a gas solid contact vessel. When gas is evenly introduced through a distribution plate at the bottom, the solid powder particles inside the container are lifted and suspended, causing the entire mass to exhibit rheological properties similar to a boiling liquid. This creates the essential conditions for subsequent uniform coating.

Not all powders possess ideal fluidization characteristics. Understanding and selecting powders that meet fluidization requirement is fundamental to ensuring a successful coating process. The fluidized behavior of a powder is primarily determined by its physical properties, such as particle size, density and surface morphology.

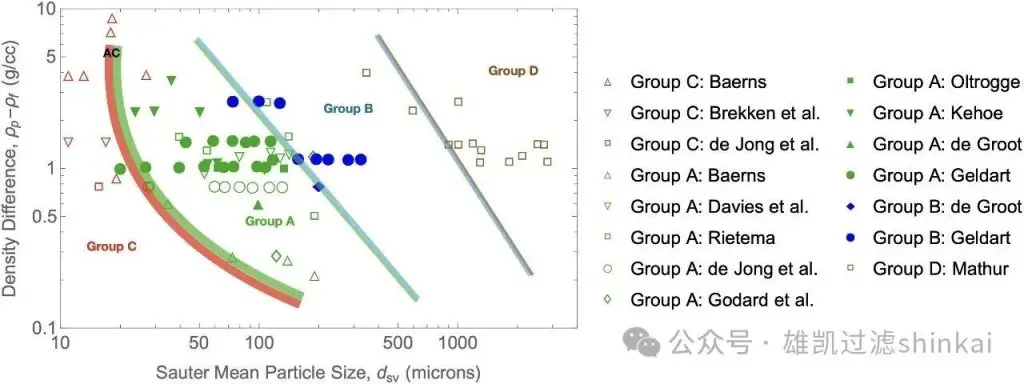

In this regard, the classical Geldart Classification provides a scientific framework for evaluation.

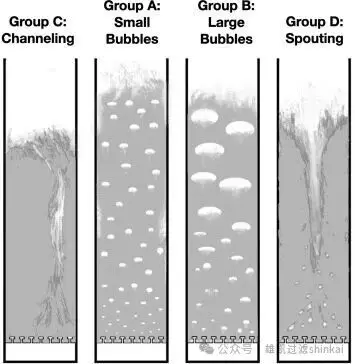

Group A (Aeratable Powders): Fine particles, typically between 45-150 μm. The bed expands uniformly upon fluidization, thus becoming ideal coating materials.

Group B (Sand-like Powders): Larger particles, mostly between 150-1000 μm. They exhibit stable bubbling fluidization once the gas velocity exceeds minimum fluidization velocity, which are also suitable for fluidized coating.

Group C (Corrosive Powders): Ultra-fine particles, 45 μm or smaller. Their strong cohesive forces often lead to channeling that makes fluidization difficult, so they are generally not used directly.

Group D (Spoutable Powders): Large, dense particles, usually larger than 1000 μm. They can only be fluidized with high gas velocity and special spouted bed techniques.

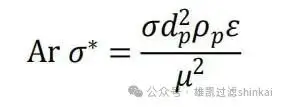

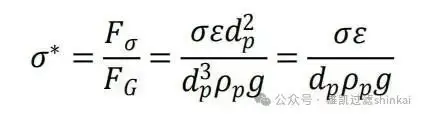

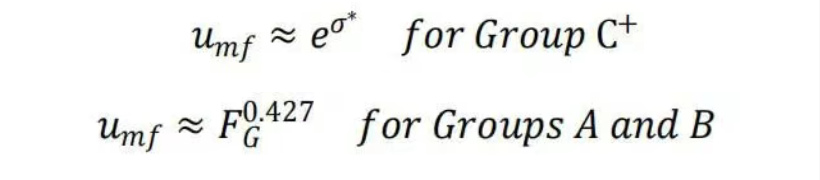

A new calculation method for the Geldart Classification was added in 2023:

Where Ar is the Archimedes number; δ* is the cohesion index (ratio of cohesive force to gravitational force); δ is the cohesively measured by instrument (Pa); F_δis the cohesive force; F_Gis the gravitational force.

The formula modifies the Geldart classification by adding a new fluidizable Group C and correspondingly different calculation method for the minimum fluidization velocity (Umf): Group C is cohesion-driven, whereas Group A and B are gravity-driven.

Core Advantages: The Technical Value of Fluidized Coating

The technical advantages of fluidized coating are what makes it stand out among numerous protective technologies.

▶ Key Technical Advantages

Environmental Friendliness & Inherent Safety: Utilizes 100% solid powders with zero Volatile Organic Compound (VOC) emissions, which eradicates environmental pollution and occupational health risks at the source.

Exceptional Thick-Film Protective Performance: Capable of perfectly covering pipe interiors, complex grooves, and sharp edges, forming a seamless, pin-hole-free, dense coating.

High Material Utilization Rate: Unattached powder can be fully recovered and recycled, achieving a comprehensive utilization rate of over 95%.High Production Efficiency & Automation Potential: The dipping process takes only seconds, and the workflow is easily integrated into automation.

Challenges and limitations

Despite all these significant advantages, fluidized coating presents inherent challenges and limitations instead of being a cure-all solution.

✘ Process and Equipment Complexity: It involves multiple steps preheating, fluidization, dip coating, and post-curing, which requires precise control and coordination. The fluidized bed, as the core component, presents complex structural design and manufacturing difficulties.

✘ Energy Consumption and Substrate limitations: Workpieces must be preheated to temperatures above 350℃.

✘ Limitations in Coating Thickness Control: While excellent for building thick films, this technology struggles to precisely control thin coatings (e.g. below 50 microns).

Shinkai’s Solution: Overcome the Process Bottlenecks for Fluidized Coating

▶ Enhancing Process Stability and Equipment Reliability to Overcome Complexity

The stability and service life of traditional fluidized beds are key constraints to their widespread application. Shinkai’s core component-high-performance porous materials has proved to be effective in enhancing system reliability with its exceptional properties:

✓ Exceptional Dimensional Stability and Component Strength: Ensures no deformation or cracking under long-term high pressure differential and thermal shock, guaranteeing consistent gas distribution over time.

✓ Superior Heat and Corrosion Resistance: Withstands operating temperatures up to 900℃ and harsh chemical environments, significantly extending equipment service life and reducing maintenance frequency and cost.

✓ Excellent Fatigue Strength and Pulse-Jet Resistance: Capable of withstanding frequent pressure fluctuations and alternating loads, ensuring stable system operation under complex working conditions.

These characteristics directly reduce equipment failure rates and maintenance difficulty, effectively addressing the challenges related to process and equipment complexity.

▶ Ensuring Coating Quality and Consistency: Breaking Through “Limitations and Boundaries”

Shinkai’s technology overcomes challenges in coating uniformity and thickness control through precise management of fluidization quality:

✓ Defined Permeability and Particle Retention: This is the core advantage of Shinkai’s porous materials. It enables extremely uniform surface aeration, fundamentally eliminating channeling and dead zones. This lays the foundation for consistent coating, particularly beneficial for large and complex workpieces.

✓ Precise Coating Thickness Uniformity: A well-tuned Shinkai Fluidized bed system ensures highly stable fluidization. Combined with accurately controlled preheat temperatures and dip-coating duration, it maintains strict coating thickness tolerances for high-quality, repeatable production.

✓ Reliable High Coating Thickness Achievement: The Shinkai process reliably achieves coating requirements from 0.5 mm and beyond, fully leveraging the thick-film advantage of fluidized bed coating while achieving defects caused by unstable fluidization.

▶ Optimizing Production Efficiency and Flexibility for Enhanced Comprehensive Benefits

Addressing the low efficiency and difficulty in color changes associated with traditional processes, Shinkai offers highly effective solutions:

✓ High Process Speed: Excellent fluidization quality allows for coating large amounts of power in a very short time, maximizing production efficiency.

✓ Rapid Color Changeover: With Shinkai-designed systems, changing the power in the feed tank can be achieved in 2 minutes or less via simple switching of the air source. This significantly enhances production line flexibility to meet modern demands for multi-variety, small-batch production.

Nanjing Shinkai’s powder fluidization technology is among the most advanced available. We not only supply core components with exceptional performance but also, based on deep industry experience, provide customized full-process solutions encompassing fluidization element design/selection, process design, valve/instrument selection, and piping design.

Committed to being your most reliable partner, Nanjing Shinkai helps you overcome production challenges and achieve exceptional coating quality and economic benefits through advanced technology and services. Please feel free to contact us to discuss your needs with our experienced engineering team.

[Reference]

[1] Ray Cocco, Jia Wei Chew. 50 years of Geldart classification [J]. Powder Technology, 2023, 428: 118861.

www. shinkaifilter.com

Email: sales01@shinkaifilter.com