Dead End Filtration System

Description

Liquid-solid separation is very common in unit operations of chemical engineering, and we will choose different filtration solution to solve the problem based on material’s temperature, flow, solid content, PH value, viscosity and related parameter. Shinkai provides dead end filtration system for batch production to solve customer’s various filtration and separation problem during production.

Applications

– Precious metal catalyst filtration in hydrogenation reaction

– Silicon tetrachloride filtration in polysilicon production

– Activated carbon filtration

– Lithium fluoride filtration

– Food and drink filtration

– Catalyst filtration in hydrogen peroxide and caprolactam production

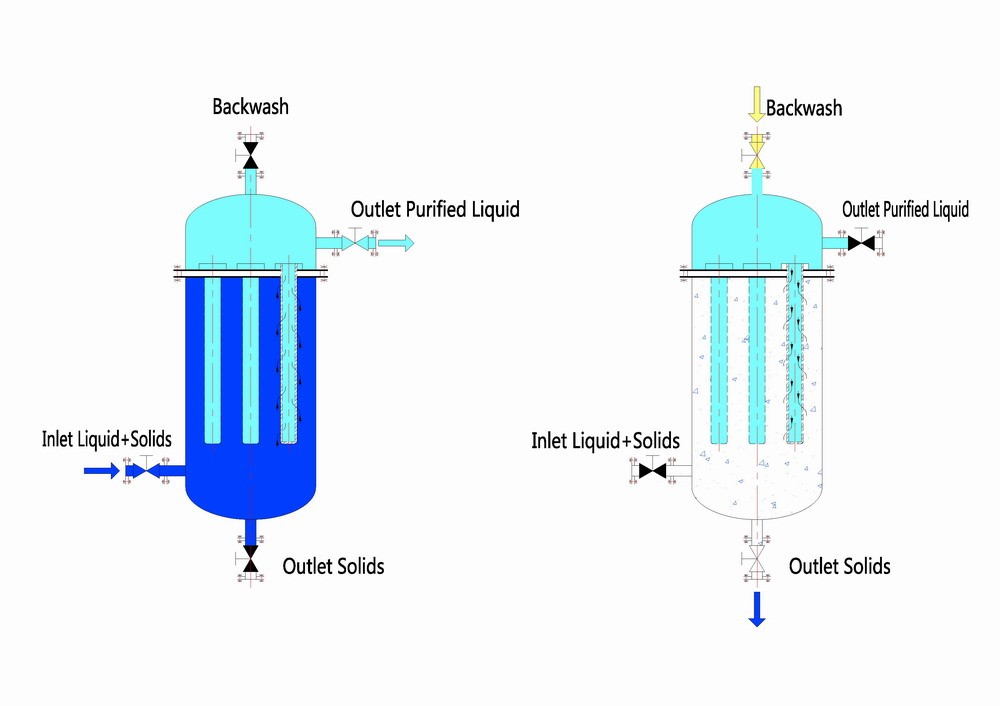

Dead End Filtration System (Outside-Inside)

This kind of filter can be used for various concentration solid fluid filtration from outside to inside, easy operation, convenient maintenance, reliable and durable filtration capability with below mentioned advantages:

– Dismounting and assembling filter cartridge conveniently.

– Filter cartridge can be dismantled integrally.

– Space among filter elements is short, structure is compact, cost is lower.

– Good back flushing performance.

– Filter surface can reach 200m2, element can be borne 0.8MPa pressure drop, and filter cake can be 20mm.

– Suitable for precious metal catalyst filtration from mother solution in fine chemical

production.

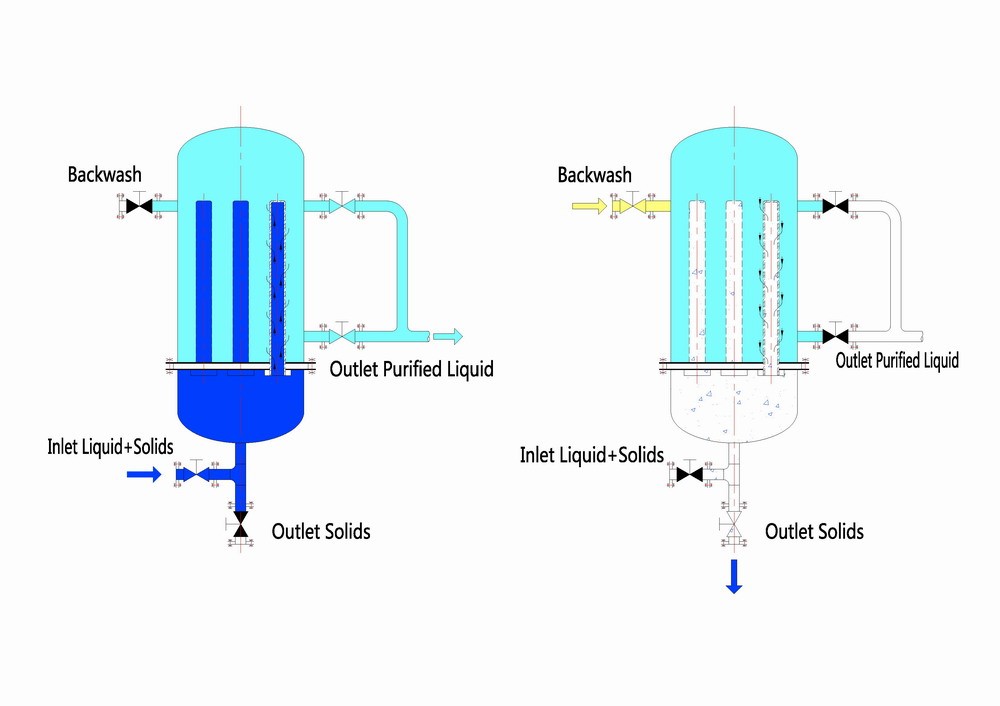

Dead End Filtration System (Inside-Outside)

This kind of filter incorporate inside-out filtration, a method and design unique by Shinkai. At the end of each filter cycle, solids are backwashed off the inside of the elements and discharged as a concentrated slurry or wet cake. Advantages include:

– Eliminates cake bridging and associated problems.

– Higher surface area to volume ratio.

– Allows for cake washing.

– Minimizes residue at the bottom of the filter.

– High solids discharge capability.

– Rapid turnaround between cycles.

– Can be used without filter aids for filtration applications.

– Positive cake retention control.

– Ideal for recovery of carbon-based precious metal catalysts, activated carbon,

organic salts, FCC catalyst from slurry oil, and pre-coat filtration applications.

– Compliance with PED, ASME, IBR, EAC, etc.