Hot Gas Filtration with Venturi Pulse Blowback

Description

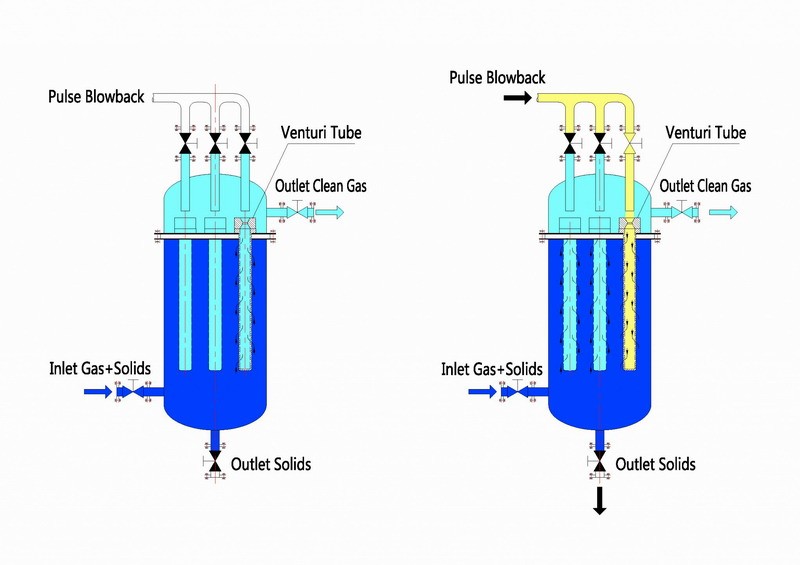

There are two types of blowback cleaning methods for hot gas filters – the pressurized blowback and the online venturi pulse blowback. With the pressurized blowback, it is necessary to isolate the filter from filtration process. With the venturi pulse blowback, the filter can remain on forward flow with no interruption of service.

In industrial production, fuel gas shall be purified before discharge into atmosphere or useful solid particles should be separated form exhaust gas along with people more and more request for environment. In order to separate solid particle from gas, Shinkai developed online venturi pulse blowback filtration system for high corrosion, high temperature and high contaminant concentration situation.

Applications

– Hot gas filtration in ethylene project

– Gas filtration in polysilicon production

– Gas filtration in coal chemical industry

– Palladium catalyst in nitric acid production

– Catalyst recovery filtration in FCC/CCR/S-ZORB

– Hot gas filtration in metallurgical industry

– Hot exhaust gas filtration in glass production

– Hot gas filtration in boilers or incinerators

Online Venturi Pulse Blowback System

This kind of system is fit for continuous filtration operation. Filter is organized by several filter element groups together, and can be cleaned by pulse jet device successively without isolate filter equipment. Each element has a venturi nozzle. The fundamental principle of the venturi pulse blowback is the use of a fast-acting gas valve, such as a pilot-operated diaphragm valve, to create a shock wave through the blowback piping and nozzles.

Advantages:

– Simple design and convenient operation

– Large disposed quantity with least reverse pulse jet

– Filter surface can reach 100m2

– Pressure drop can reach 0.8MPa

– Sufficient thermal strength up to 900℃

– Good blowback performance

– Suitable for PE powder, magnesium oxide solid, PP powder recovery, high temperature fly ash filtration in coal gasification industry as well as catalyst recovery from fluid bed reactor.

– Compliance with PED, ASME, IBR, EAC, etc.