Sinter Metal Wire Mesh Filter Elements

Description

Sintered wire mesh filter is rolled by multi-layer (usually five layers) 316L or 304L stainless steel wire, sintered by high temperature vacuum, argon arc or plasma welding.

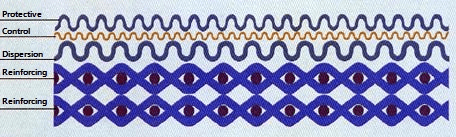

Sintered wire mesh filter (XKW) is rolled by multi-layer (usually five layers) 316L or 304L stainless steel wire, sintered by high temperature vacuum, argon arc or plasma welding. The size and distribution of the holes are adjusted by selecting the wire diameter, the mesh size and the weaving method of the wire mesh.

Features

– Defined permeability and particle size retention

– Good mechanical properties

– Corrosion resistance

– Good back flush flow and durable performance

– High temperature resistance

Specifications

– Dimensions: Wrought into tubes, disc, pleated or customized

– Diameter for tubes: 20 ~ 1000 mm

– Filtration precision: 2 ~ 200μm

Materials of Construction

Stainless steels (304L, 316L)

Applications

Fluidization in steel industry

Powder homogenization

Food & Beverage industry

Filtration, washing and drying in the pharmaceutical industry