Sintered Metal Sparger for Fermentation Tank Stainless Steel

Description

The particular approach is that gas is directly injected in liquid through a porous Shinkai filter. Using the velocity and turbulence of the flowing liquid, this configuration is the most efficient diffuser systems since it results in fine bubbles, for superior performance.

Spargers are necessary elements of Bioreactors, fermentation tank, carbonated beverages, and cooking oils oxygen stripping, etc. In many applications, we help our customers to maximize process efficiency by recommending and designing the most suitable solution based on a variety of sparger units.

Traditional bio-fermentation technology is ripe for innovation. Our bio-fermentation solutions allow for higher gas absorption than standard and can significantly lower energy costs by decreasing the agitation needed in your bio-ferments. Enabling faster absorption allows for increased cycle times and significant time savings.

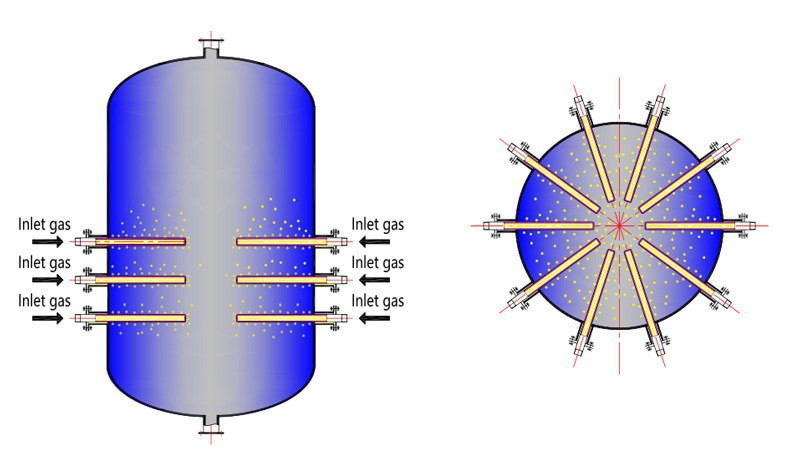

Bio-fermentation sparger

Static sparger

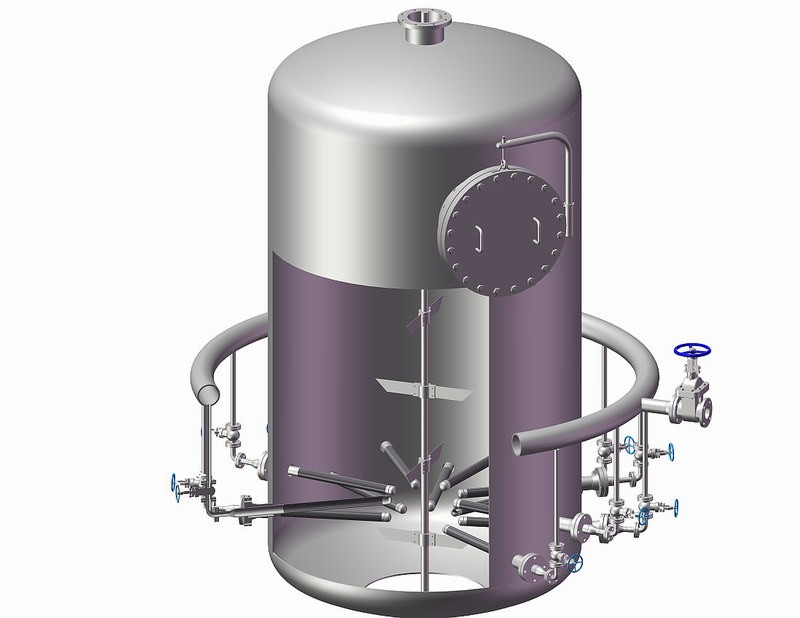

Dynamic pipeline sparger

Porous metal micro sparger

Feature

– Shape stability, self-supporting as structural elements even at high pressure.

– Good mechanical properties

– High temperature resistance, up to 900℃.

– Defined permeability and particle size retention

– Corrosion resistance

– Support grid in catalyst reaction

– Dispersing cooling material in a high temperature environment

– Filtration, washing and drying in the pharmaceutical industry

Materials of Construction

Stainless steels (304L, 316L)

Applications

– CO2 sparging for carbonated beverages and beer

– Fine chemical industry

– Oxygen or air sparging to enhance cell growth in fermentation tanks

– Aquaculture industry

– Hydrogen sparging for a broad spectrum of chemical hydrogenation reactions

– Air injection for mixing liquids in a vessel.

– Sparging air, oxygen, or other gases into reactors for improved performance.