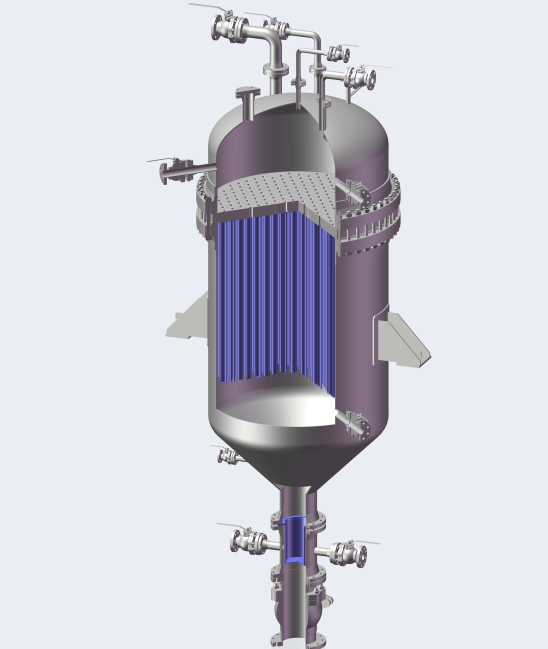

Catalyst Filter

Description

In order to solve the problem of catalyst leakage in chemical industry, the catalyst filtration system designed by Shinkai with using the sinter porous metal filter to handle extreme environment and intermittent production, which has perfectly solved the liquid-solid separation problem and create significant value for customers.

In fine chemical production, hydrogenation reaction definitely requires precious metal catalyst. After the reaction is completed, the catalyst always goes into the reaction solution. Sintered Metal Filter can be used to separate product and catalyst.

Feature

– Shape stability, self-supporting as structural elements even at high

pressure.

– Good mechanical properties

– High temperature resistance, up to 900℃.

– Corrosion resistance

– Good back flushing performance

– Solving environment protection problem, completely customization design,

– Automatically controlling, reducing worker exposure to harsh chemicals

– Eliminate the problem of filter cake accumulation

– Compliance with PED, ASME, IBR, EAC, etc.

Applications

Oil refining industry (FCC, CCR)

Polysilicon industry

High temperature Fischer

Tropsch Synthesis

Deacon process

Fluidized bed reactor

Organ silicone

Materials of Construction

Stainless steels (304L, 316L)

Titanium and its alloys

Monel®

Inconel®

Hastelloy® B, C and X

Nickel

Iron and aluminum alloy