Loop Heat Pipes (LHP) are thermal management devices that utilize phase change of a working fluid to achieve highly efficient heat transfer. The core component is a porous metal powder wick evaporator. This system relies on micron-scale pores to generate capillary forces that drive the cyclic flow of the phase-change working fluid between hot and cold zones, operating without any external power input. Thanks to their excellent heat transfer performance and flexibility, porous metal wick loop heat pipes are widely used in spacecraft thermal control, high-power electronics cooling, ad industrial waste heat recovery applications.

Heat Transfer Principles in LHPs and Types of Capillary Wicks

▶ Operating Principle

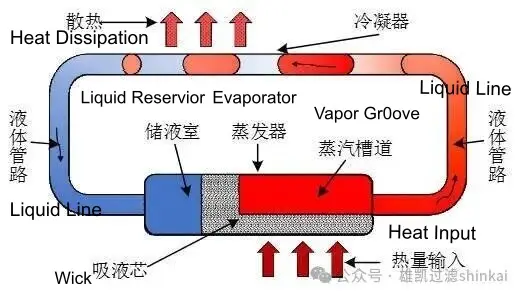

A loop heat pipe primarily consists of an evaporator, condenser, liquid reservior, and vapor and liquid transport lines. A key feature that distinguishes it from conventional heat pipes is the liquid feed line (for liquid return tube), which directs condensed liquid directly into the center of the evaporator.

LHP is based on a phase-change cycle and capillary force-driven mechanism. When heat is applied to the evaporator, the working fluid evaporates at the outer surface of the capillary wick. The vapor flows through the vapor line to the condenser, where it condenses and is subcooled. The subcooled liquid then returns via the liquid feed line to the central liquid core of the evaporator, replenishing the wick. The entire cycle is driven solely by the capillary pressure generated by the wick, requiring no external power.

▶ Thermodynamic Analysis

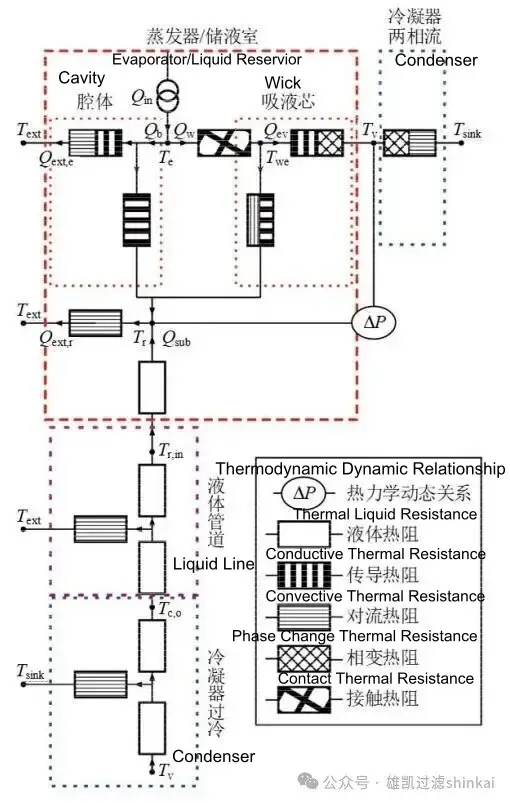

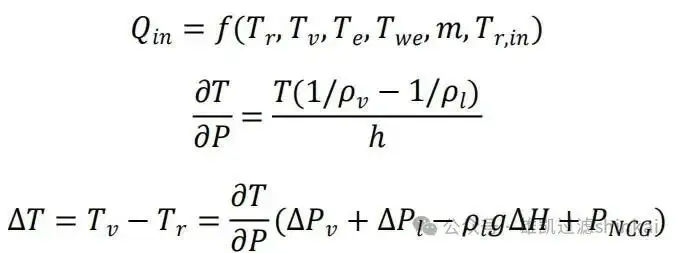

An energy and thermodynamic nodal network diagram clearly illustrates the overall heat flow and temperature parameters at key points in the LHP cycle:

Figure 2: Nodal Network Diagram of LHP Temperature and Heat Flow Analysis

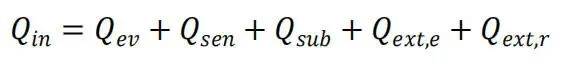

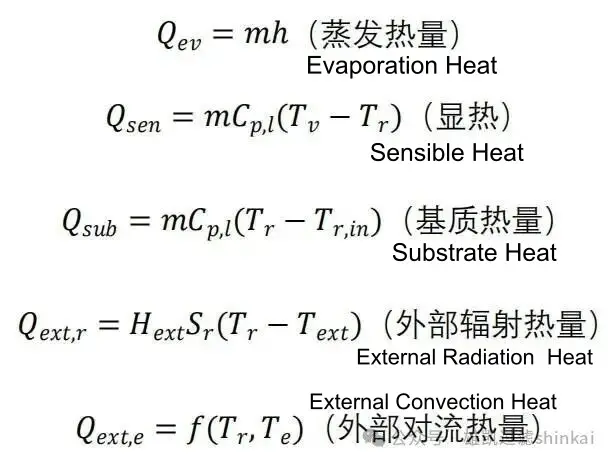

Based on the system-wide analysis formula, an energy conservation model for the system heat flow can be established:

Where:

Qin: Total heat input

m: Mass flow rate

h: Latent heat of vaporization

Cp: Specific heat capacity

H: Convection coefficient

S: Surface area

T: Temperature

ρ: Density

g: Gravitational acceleration

ΔH: Height difference

PNCG: Non-condensable gas pressure

The temperature-pressure characteristic relationship formula is:

The equation and the nodal network diagram quantitatively describe the energy distribution and pressure balance within the LHP system, providing a theoretical foundation for LHP research.

The evaporator is the core of the LHP, serving both to absorb heat and provide the driving force for circulation. Its key element-the capillary wick-contains pores that form pathways for the working fluid, ensuring uniform, low-resistance axial replenishment.

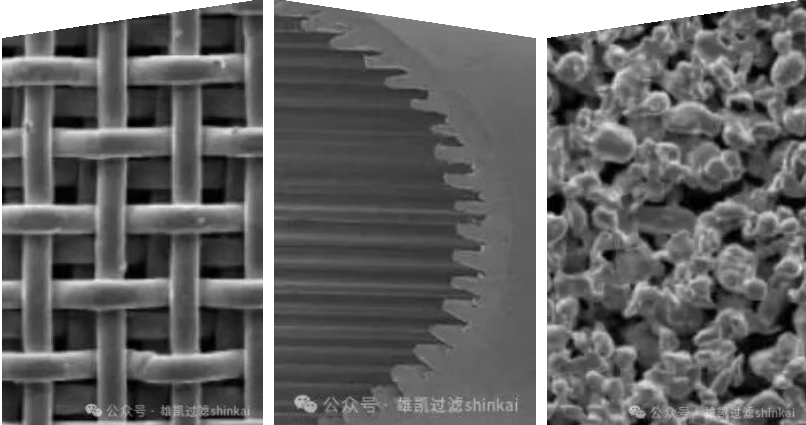

There are three primary structural types of capillary wicks:

Metal Screen Wick: A mesh of specific fineness attached to the inner wall of the evaporator. Simple to manufacture.

Grooved Wick: Micro-grooves (axial or circumferential) machined into the evaporator’s inner wall via extrusion or turning.

Sintered Metal Wick: Created by sintering metal powders or fibers. This is the most widely used and technologically mature form, offering a broad range of pore structures.

Capillary Wick Quality Selection and Challenges

In practical engineering applications, Loop Heat Pipes face two primary challenges related to the manufacturing quality of the capillary wick: start-up characteristics and operational stability.

▶ Start-up Issues

Start-up reliability is a key bottleneck limiting LHP applications. An unreasonably designed wick structure often leads to the following risks:

✗ Temperature Exceedance: At the moment of start-up, if liquid supply is insufficient, the evaporator temperature may spike sharply, exceeding the instrument’s allowable heat resistance limit.

✗ High Steady-State Temperature: Certain start-up methods (e.g., nucleate boiling start-up with high superheat) can cause the system’s steady-state operating temperature to remain elevated after start-up, affecting cooling efficiency.

▶Operational Instability

LHPs often exhibit complex instabilities during operation, frequently related to the pore uniformity and permeability of the capillary wick:

✗ Temperature Hysteresis and Fluctuation: System temperature may exhibit lag or sustained periodic oscillations.

✗ Working Fluid Reverse Flow: An abnormal phenomenon where fluid flows backward, disrupting the thermal cycle balance.

Shinkai Solution: High-performance Porous Metal Powder Wicks for Loop Heat Pipes

Addressing the pain points of LHPs such as difficult star-up, temperature fluctuations, and operational instability, Nanjing Shinkai leverages advanced metal powder sintering technology to offer dedicated porous metal powder wick solutions for Loop Heat Pipes.

By optimizing pore structure (high-precision filtration) and material strength, our products effectively resolve issues like high liquid supply resistance in the wick, susceptibility to vapor lock, and poor high-temperature performance, significantly enhancing the start-up success rate and operational stability of LHPs.

▶ Precise Pore Size Control for Optimized Start-up

O.1 μm High Filtration Precision: The uniform distribution of micron-scale pores effectively reduces the resistance to working fluid infiltration, enabling rapid wetting and replenishment at the evaporation interface. This significantly shortens start-up time and suppresses temperature spikes caused by local dry-out.

▶ High Strength and Low Flow Resistance for Stable Operation

Withstands Pressure up to 50 bar, high surface finish: Excellent mechanical strength ensures the structural integrity of the capillary wick under high-pressure differential cycling, preventing flow channel blockage due to pressure-induced deformation.

▶ Extreme Environment Tolerance for Enhanced System Reliability

High-Temperature Resistant (900℃), strong Corrosion Resistance, High Impact Resistant: Capable of long-term stable operation in extreme temperatures and corrosive working fluid environments. Superior resistance to alternating loads ensures consistent thermal control performance of the heat pipe over long-term operation, extending the device’s service life.

▶ Excellent Permeability and Regenerability

Good Gas Permeability, Superior Separation Effect, Easy to Regenerate: Good permeability ensures high efficiency of the working fluid cycle, while effective backwashing capability reduces subsequent maintenance difficulty and improves system cost-effectiveness.

▶ Diversified Alloy Material System

To meet the chemical compatibility requirements of different working fluids (e.g. ammonia, acetone, water) and the physical property needs of specific application scenarios, Nanjing Shinkai offers the following range of alloy material choices:

General Stainless Steels: 304L, 316L

Lightweight & High-Performance Metal: Titanium and its alloys, Nickel metal

Special Corrosion & High-Temperature Resistant Alloys: Monel, Inconel, Hastelloy B, C, X

Other Specialty Materials: Customization available upon request.

Nanjing Shinkai is committed to providing precise and reliable core components for thermal management systems through high-standard porous material technology, helping your industrial systems achieve safer and more efficient operation. If your company is facing challenges with Loop Heat Pipes, please feel free to contact us. Let’s work together to explore the optimal solution.

Reference:

[3] Ju-hong Wu, Yong TangLong-sheng Lu. Capillary force of a novel skew-grooved wick structure for micro heat pipes[J]. Journal of Central South University of Techno. 2011, 18: 2170–2175.

www. shinkaifilter.com

Email: sales01@shinkaifilter.com