Introduction

Pulverized coal is a micrometer-sized powder produced by pulverized coal. Through pulverization, it achieves rapid and complete combustion similar to a gas, significantly increasing combustion efficiency. This highly efficient combustion method is a core technology for driving steam generator in large power plants.

Pulverized coal offers several significant advantages in industrial production:

High-Efficiency Combustion & Fuel Utilization: Complete combustion with high thermal energy conversion rate.

Stable & Controllable Combustion Rate: Facilities load adjustment to meet process demands.

Rapid Response & Heating: Quick star-up/shutdown and flexible operation.

Easy Automation & Precise Control: Seamless integration with modern control systems.

Thanks to these advantages, pulverized coal has become a key raw material in modern energy and chemical industries, with major applications including:

Large-scale power generation and co-generation

Coal-water slurry preparationCoal gasification

However, pulverized coal conveying remains a critical technical challenge. The core difficulty lies in the tendency of ultra-fine coal particles to interrupt flow due to agglomeration, bridging, or channeling. The key to achieving stable and efficient conveying is to bring the coal powder into a uniform fluidized state, giving it fluid-like properties.

Challenges in Pulverized Coal Conveying

The entire process, from raw coal pre-treatment to final boiler combustion, depends on the connecting step, pulverized coal conveying, which faces severe challenges. These difficulties stem from the inherently “unruly” physical nature of ultra-fine coal powder. These micron-sized particles have a very large specific surface area, causing inter-particle van der Waals and electrostatic forces to far exceed their own gravity leading to a series of stubborn flow problems:

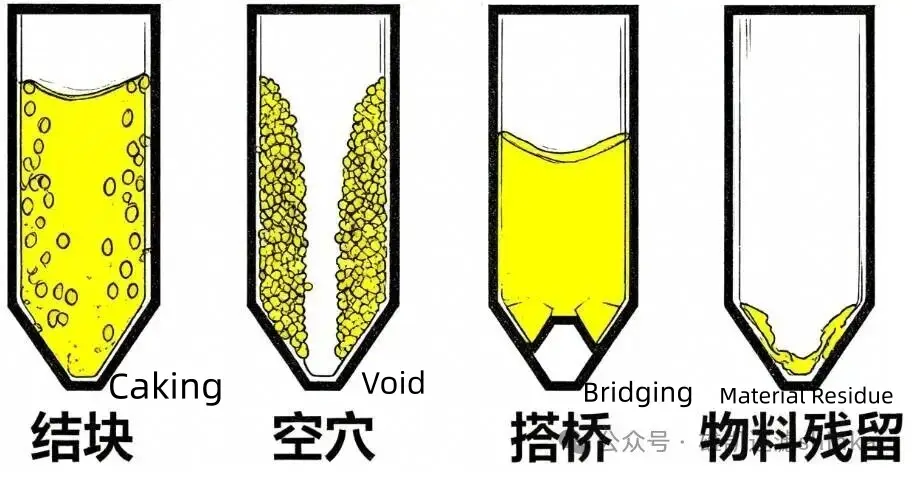

Agglomeration: Particles attract each other like magnets, forming hard-to-disperse clumps that destroy material uniformity.

Bridging: At constrictions in silos or pipes, coal particles interlock, forming stable arch-like structures that act as “bridges,” completely blocking the passage and halting flow.

Channeling: Under gravity, airflow often penetrates only a narrow path, while large amount of surrounding coal remain stagnant in a “dead bed”, which results in low conveying efficiency and underutilization of silo capacity.

These issues could cause production stoppage, equipment wear, and soaring maintenance costs. More seriously, unstable conveying directly affects the efficiency and safety of downstream combustion or gasification processes, potentially leading to major safety incidents like dust explosions.Taming these “unruly” micron-dust particles is the key to fix all problems. It lies in achieving a uniform fluidized state for the coal powder, transforming it from a “solid” into a “fluid”, thereby exhibiting excellent liquid-like flow characteristics.

Shinkai’s Solution: Professional Fluidization System

Confronting the numerous challenges of ultra-fine powder conveying, Nanjing Shinkai leverages deep R&D expertise and extensive engineering experience to successfully develop a complete set of advanced powder fluidization and handling system. It integrates core components such as aeration cones, fluidizing pads,and pipe aerators, designed to fundamentally target and resolve the pain points of coal powder conveying.

Targeted Solutions for Three Major Challenges:

- Eliminating “Bridge” & “Dead Zones”- Achieving Full Silo Activation

Aeration cones and fluidizing pads are installed in the silo cone or other critical areas. Utilizing their gas permeability, these components inject precisely controlled low-pressure air into the coal powder layer, forming an “air cushion.” This cushion effectively breaks the cohesive forces between pictures, eliminating the mechanical conditions for arch formation. The entire silo of coal powder is uniformly “activated,” achieving “mass flow” instead of “funnel flow,” fundamentally resolving discharge issues and maximizing silo utilization. - Preventing Agglomeration – Conveying Uniformity

The continuous, uniform airflow provided by fluidizing pads and pipe aerators not only promotes flow but also disperses and agitates agglomerated coal clusters. Plus their efficient back-blowing effect, this prevents filter media surface clogging caused by coal adhesion, which ensures long-term stable system operation and uniform material conveyance. - Resolving “Channeling” & Pipeline Blockages – Ensuring Long-Distance Stable ConveyingPipe aerators are strategically installed at key points along the conveying pipeline (e.g. bends, vertical sections). They supplement “boosting” airflow into the pipeline in pulsed or continuous modes, re-fluidizing settled particles, maintaining the suspended state of the coal powder, and preventing blockages. In this way, stable and reliable conveying even through complex pipeline routes can be ensured.

Core Product Advantages — Robust Performance Under Extreme Working Conditions

The realization of the above functions stems from the exceptional physical and chemical properties of Shinkai’s core components that directly address the harsh demands of coal powder conveying:

Ultra-Wide Temperature Range (Up to 900℃): Ideal for the high-temperature environments in coal preparation and conveying (e.g. hot air conveying systems), ensuring no degradation of material performance.

High Mechanical Strength & Fatigue Resistance: Withstands significant static pressure from the material column and continuous vibration during pneumatic conveying, with resistance to damage, a long service life, and reduced downtime risks and maintenance costs from equipment failure.

Excellent Weldability: Ensures leak-tight seals and structural integrity at connections between fluidized elements, silos and pipelines and prevents powder leakage and energy loss.

Strong Corrosion Resistance to Solvents, Acids and Alkalis: Suitable only only for coal powder but aslo for handling corrosive atmospheres in chemical process (e.g. coal gasification), broadening the application scope.

Proven in Widespread Industrial Applications:

Shinkai’s solutions have been successfully implemented in numerous global industrial and manufacturing enterprises, with proven performance in key sectors:

Energy & Power: pneumatic conveying of fly ash, fly ash filtration, and separation, ensuring efficient and clean operation of power plant ash handling systems.

Coal Chemical Industry: Stable conveying of pulverized coal feedstock in coal gasification processes; used in quench water filtration in MTO (Methanol to Olefins) units to protect downstream equipment.

Fine Chemicals: Applied in precision filtration steps during the production processes of products like low-temperature methanol, caprolactam, hydrogen peroxide, demonstrating excellent capability in handling complex materials.

From energy to chemicals, Nanjing Shinkai is empowering global industrial users to master micron-dust with its professional fluidization technology, solving the long-standing challenges of ultra-fine powder conveying and creating sustained value.

Case Studies

Nanjing Shinkai’s expert teams remain focused on R&D and innovation and committed to empowering industrial processes for global customers. We not only provide state-of-the-art technical solutions.

Case Study 1: Solving Raw Coal Powder Conveying Challenges for Gasification

A gas distribution control company faced bottlenecks in steadily conveying micro-sized coal powder into a gasifier. Shinkai developed a customized powder fluidization system based on a deep understanding of their process needs. The new system achieved smooth, efficient material conveyance without altering material properties, ensuring the stability of the subsequent gasification process.

Case Study 2: Conveying Ultra-Fine Coal Powder with Specific Material Requirements

A Japanese powder handling company struggled long-term with agglomeration and bridging of ultra-fine coal powder, with the client specifying sintered plate as the mandatory material for fluidization elements. Through close collaboration, Shinkai not only supplied core components meeting the material requirement but also designed a complete conveying solution fully compatible with the client’s manufacturing system, ultimately resolving their persistent production challenges.

www.shinkaifilter.com

Email: sales01@shinkaifilter.com