Hot Gas Dedusting System

Hot Gas Dedusting System

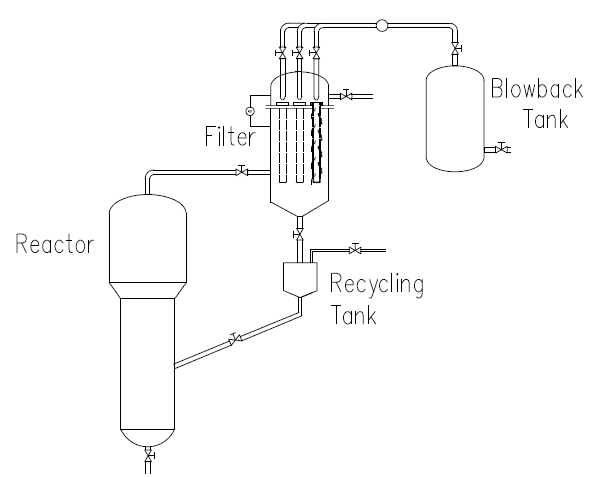

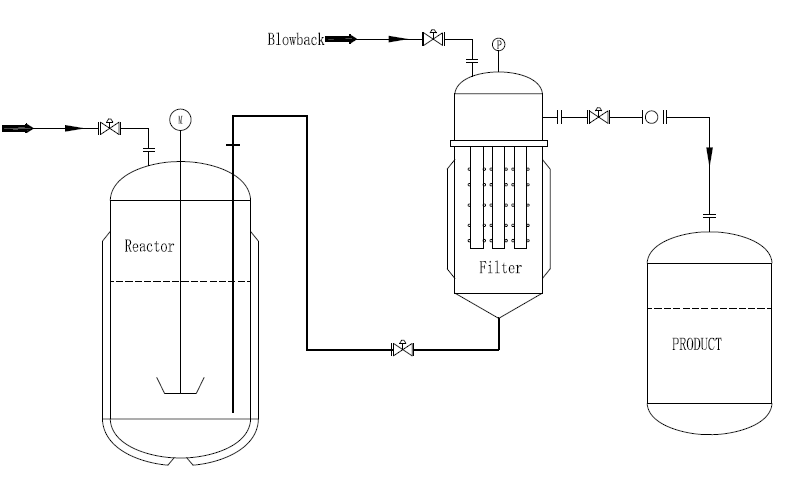

The hot gas dedusting system uses hot gas online pulse blowback filter designed by Shinkai as the key equipment, and has the dust recovery process and other auxiliary processes according to the working conditions. It can realize continuous filtration and automatic discharge without manual operation.

With a wide selection of alloys to choose from, such as stainless steel, Hastelloy, and Monel, Shinkai’s hot gas dedusting system can accommodate a wide range of temperature and chemistry.

| Variables | Specifications |

|---|---|

| Temperature Ranges | 0-900℃ |

| Pressure Drop | ≤10kpa |

| Filter Media Grade Options | 0.1-50μm |

| Available Alloys | 316L,Monel®400, Inconel® 600, Hastelloy® X, C-276, C-22 |

| Typical Particle Capture | 99.8% |

The catalyst filter produced by Shinkai has the function of backwashing, which can be recycled and fully automated controlled.

With a wide selection of alloys to choose from, such as stainless steel, Hastelloy, and Monel, Shinkai’s Catalyst filtration and separation system can accommodate a wide range of chemistry.

Applications

– Precious metal catalyst filtration in hydrogenation reaction

– Precious metal catalyst filtration in isomerisation reaction

Advantages:

– Online backwashing, without manual operation.

– No catalyst leakage.

– Reduced maintenance and downtime.

– Less utility consumption.

– Less safety concerns

– Fully-Automatic operation

Applications

– Precious metal catalyst filtration in hydrogenation reaction

– Precious metal catalyst filtration in isomerisation reaction

Advantages:

– Online backwashing, without manual operation.

– No catalyst leakage.

– Reduced maintenance and downtime.

– Less utility consumption.

– Less safety concerns

– Fully-Automatic operation